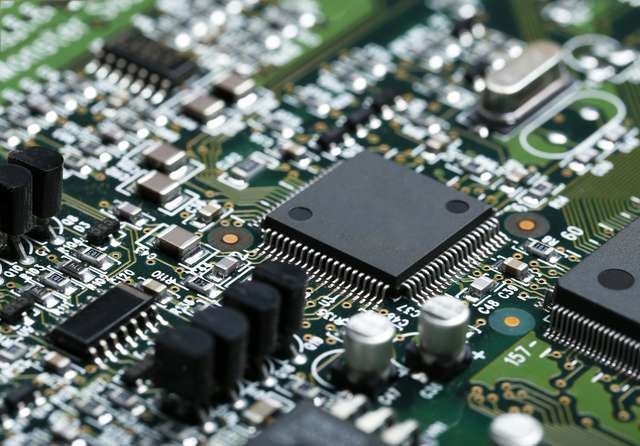

The ongoing war in Ukraine has caused a ripple effect across many industries, including the chip market. One of the key issues is the production of high-quality neon, which is used in lasers and chips in US factories. Ukraine is responsible for producing around 90% of the world's high-quality neon, which makes this conflict particularly significant for the chip industry.

Table of Contents

The production of high-quality neon in Ukraine is concentrated in the city of Lviv, which is situated in the western part of the country. This region has been relatively stable throughout the conflict, but the ongoing tensions have still had an impact on production. The transportation of neon from Lviv to other parts of the world has become more challenging due to the conflict, leading to delays and higher costs.

Serious dependence

The chip market is highly dependent on neon, which is used in the manufacturing process to create lasers that are essential for etching tiny circuits onto silicon wafers. Without neon, the production of chips would be significantly slower and more expensive. The shortage of neon has led to an increase in chip prices, making it more difficult for manufacturers to produce affordable products.

The impact of the neon shortage on the chip market has been felt worldwide. Companies such as Intel and Samsung have reported difficulties in securing adequate supplies of neon, leading to delays in production and increased costs. The shortage has also led to a surge in demand for alternatives, such as argon, which can be used in place of neon. However, these alternatives are often more expensive and less efficient than neon, which further compounds the problem.

The situation in Ukraine is complex and multifaceted, but the impact on the chip market is clear. The conflict has disrupted the production and transportation of high-quality neon, leading to a shortage that has affected the entire industry. The shortage has led to higher prices and delays in production, making it more difficult for manufacturers to meet demand for their products.

Butterfly effect

The chip industry is a vital component of the global economy, and any disruptions in the supply chain can have far-reaching consequences. The shortage of neon is just one example of how conflicts in one part of the world can have a ripple effect across industries and countries. It highlights the need for a stable and predictable supply chain to ensure that manufacturers can continue to produce affordable products for consumers worldwide.

In conclusion, the ongoing conflict in Ukraine has had a significant impact on the chip market, specifically regarding the shortage of high-quality neon. With Ukraine responsible for producing 90% of the world's high-quality neon, any disruptions to production and transportation have significant consequences. The shortage has led to higher prices and delays in production, making it more difficult for manufacturers to meet demand for their products. The situation highlights the importance of a stable and predictable supply chain to ensure that the chip industry can continue to thrive.

Foto: https://www.freepik.com/free-photo/closeup-electronic-circuit-board-with-cpu-microchip-electronic-components-background_1193002.htm#query=chip&position=12&from_view=search&track=sph / Image by xb100 / on Freepik